Wastewater Treatment with Anaerobic WWTP Technology

Wastes have very high levels of COD, organic matter content, and BOD which can potentially pollute the environment. Therefore, wastewater treatment must be carried out properly before being discharged to the final disposal.

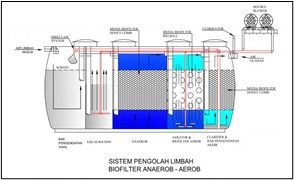

Waste treatment is carried out using water treatment (IPAL/WWTP). Waste treatment containing organic loads can be treated aerobically or anaerobically. Aerobic processes are usually used to treat wastes with a low organic load, while anaerobic processes are generally used for wastes with very high organic loads. The wastewater treatment process with the Anaerobic WWTP system is a wastewater treatment system without the use of oxygen and is carried out by anaerobic decomposing bacteria. The hallmark of this system is the formation of methane gas (CH4) which has advantages and advantages over aerobic processes.

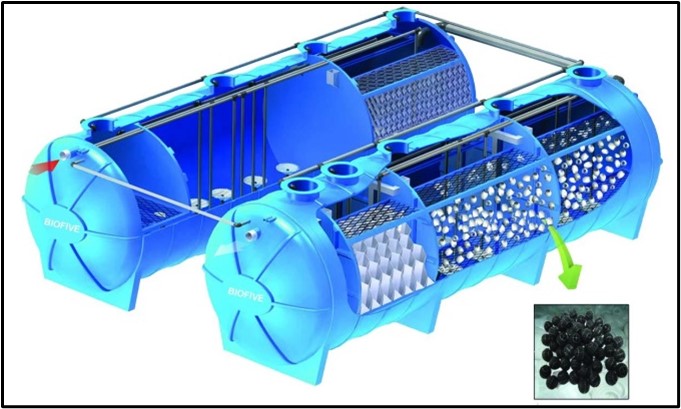

In the application of anaerobic WWTP, this system uses biofilter media in an anaerobic reactor or internal circulation (IC Reactor). The biofilter media used aims to attach microorganisms (anaerobic bacteria) so that they are useful for the proliferation of these microorganisms. IC Reactor is a form of anaerobic digester or biodigester which is a technology that utilizes a biological process in which organic matter is decomposed by anaerobic microorganisms in the absence of dissolved oxygen (anaerobic conditions). The digester from the IC Reactor produces biogas with a concentration of C80% methane. In the reactor, a microorganism growth system was chosen to be attached to the growing medium with the hope that the distribution of microorganisms was evenly distributed throughout the reactor without the aid of energy.

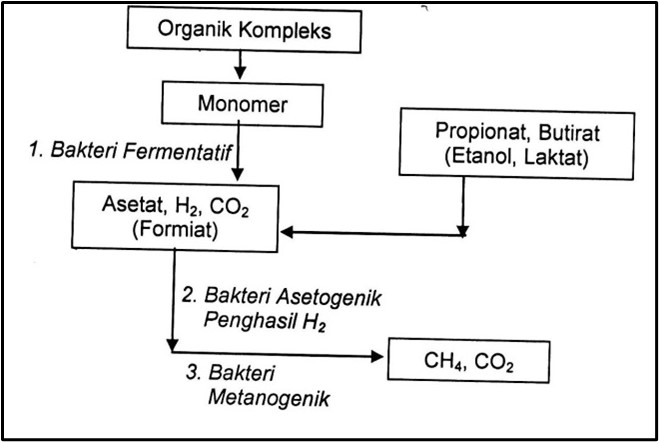

The anaerobic process that occurs is generally divided into 3 stages; the hydration and fermentation stages; the stage of formation of acetic acid; and the stage of methane formation.

An example of an anaerobic treatment process is the anaerobic filter system or also known as the Fixed Bed Reactor or Fixed Film Reactor. Fixed Bed Reactor is a waste treatment method that applies anaerobic biological processes using an attached microorganism growth system.

Microorganisms grow and develop by sticking into a medium. In the reactor, a microorganism growth system is chosen to be attached to the growing medium in the hope that the distribution of microorganisms is evenly distributed throughout the reactor without the aid of energy (Padmono 2003).

Advantages of using WWTP Anaerobic:

- Does not require a large space,

- This industrial wastewater treatment system has a low investment cost,

- Produce effluent that can be reused for energy needs such as methane gas (CH4) which is formed from the fermentation process which can be used as a source of electricity,

- Has a high degree of stability,

- Low biological artificial sludge products,

- Low nutrient requirements.

-

Expensive Goods Durable vs Buy Cheaper But Replaced Repeatedly, Which is More Worth it?

We all often consider in detail the items we want to buy. Price and quality are definitely a very important...READ MORE -

World Water Day, The Importance of Maintaining Clean Water for the Future

World Water Day is a celebration that is held every year to make people around the world aware of the...READ MORE -

3 Ways To Celebrate Earth Day

World Earth Day is celebrated on April 22 each year. Earth Day aims to raise awareness among the masses...READ MORE